Powering Precision.

Perfecting Induction.

Your Induction technology Specialists

Dependable. Efficient. Experienced.

With over three decades of experience, we are the go-to experts for fast, reliable, and professional service, repairs and replacement for all types of induction furnaces and related components.

As manufacturers, we work closely with our parent company—an industry-leading innovator—to produce state-of-the-art induction equipment as well as electric- and gas-fired industrial furnaces, tailored to your needs.

8000 SF production area 1500 SF storage space 1500 SF office

Testing area, 5 to overhead crane, separate dismantling area

50+ combined experience founded in 2002

10+ employees (IPS) 100+ extrutec group

Products

What we offer and manufacture:

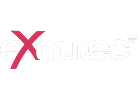

- Complete high-efficiency billet heaters

- Water- or air-cooled bus bar, etc.

- Channel melting furnace, repair and replacement of transformer core, air- and water-cooled bushings, water-cooled leads/cables, etc.)

- Coating line inductors, complete rebuilding, refractory replacement and components

- Forging coils and components, repair and replacement (open style or cast refractory), water- or air-cooled skid rails, water-cooled leads/cables, etc. – from all known brands

- IGBT converters for various applications, e.g. billet heating, melting,

- Induction coils for various applications, e.g. billet heating, melting, forging, coating, etc.

- Water-cooled bushings for channel inductors

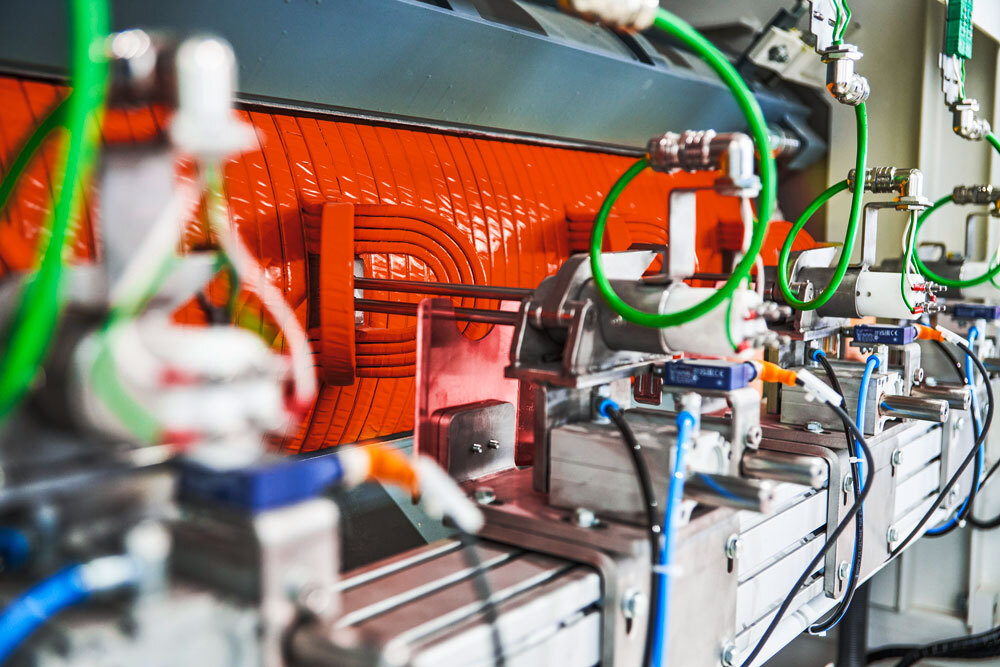

- Hollow and solid cast channel molds made of copper, iron or steel complete yokes/shunts and insulation

- Yoke insulations & power leads/cables

- Refractory segments & furnace lids, top and bottom castable shapes

- Individual components such as chokes and transformers in air- & water-cooled design

- flux concentrator

- Busbars, air- or water-cooled

Service

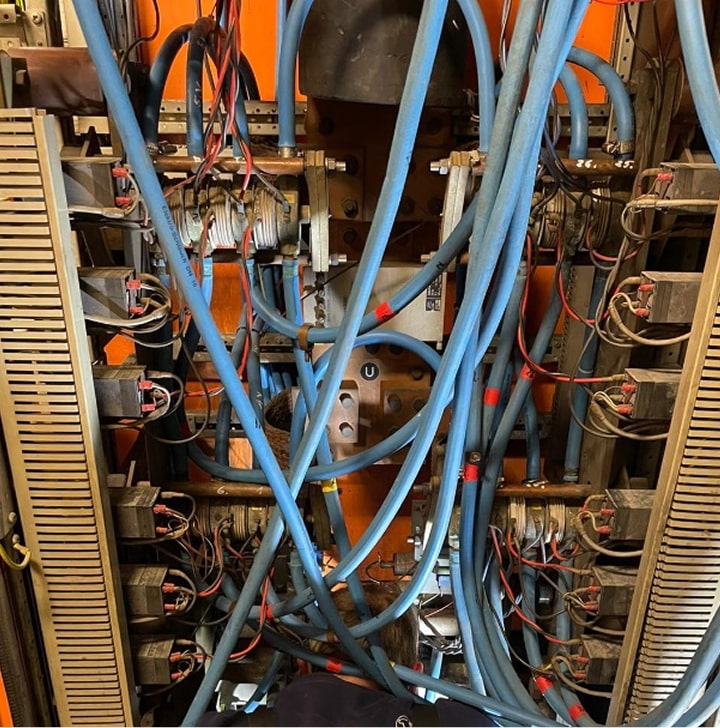

We are experts in repairing, maintaining and supplying components for all OEM equipment, such as:

- Induction billet heating equipment

- Complete coreless induction furnaces

- Inductors for channel furnaces

- Coreless furnace coils

- Furnace lids/top caps

- Channel furnaces

- Inductors for forging processes

- Bushings

- Power leads/cables

- Magnetic yokes

- …

Retrofitting: Your partner from A to Z.

We are your reliable partner for the support of your induction equipment or induction furnace over its entire lifecycle. Production changes, technological advancements and varying process conditions require continuous improvement of existing systems. We are your reliable partner throughout the entire modernization process, offering the following measures:

- Performance upgrades for induction furnaces and systems

- Modifications of furnace geometry and coil

- Modification to the power supply

- Power supply upgrades; convert mechanical switchgear to IGBT converter technology

- Controls upgrades

- Modification to the furnace lid/top and bottom castable shapes

Contact

Good to be connected.

General Manager

Tom Kearny

Phone: +1-330-779-3456

Technical Director

Stefan Beer

Phone: +1-330-779-3456

Key Account Manager

Michael Werner

Phone: +1-330-779-3456

Production Manager

Mark Green

Phone: +1-330-779-3456

Office Manager

Stacy Collins

Phone: +1-330-779-3456

Managing Partner/ CEO

Uwe Günter

Phone: +49-7732/939-1390

Business Unit Manager Sales/ Business Development

Jan Günter

Phone: +49-7732/939-1390